Pressure Change Method

The pressure change method using absolute/relative pressure sensors is one of the simplest and most reliable leak test methods on the market.

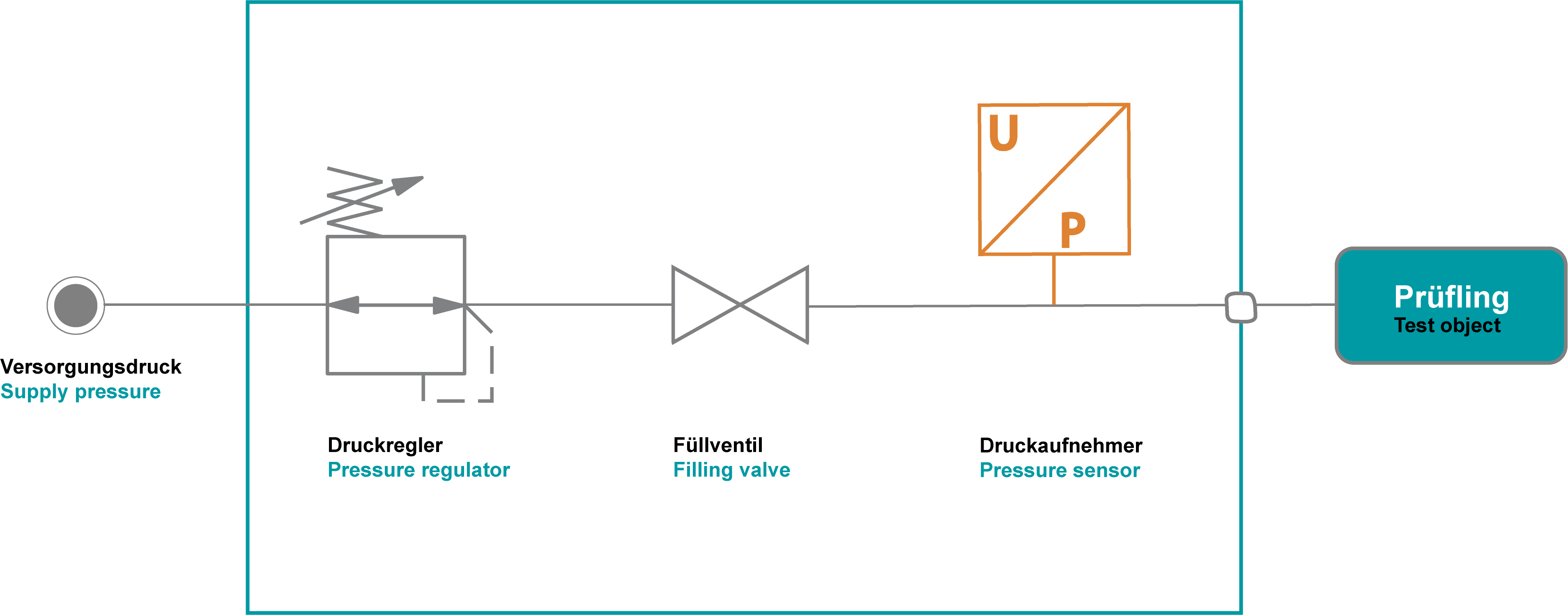

The test specimen is subjected to overpressure or vacuum and the pressure change is determined over time. A distinction is made between two different sensor types with which the pressure change can be determined.

- With absolute pressure measurement, the test pressure is measured in relation to the ideal vacuum (0 bar absolute).

- The relative pressure measurement compares the test pressure in the test item with the ambient pressure. If the test pressure is greater than the ambient pressure, it is referred to as overpressure, or if it is less than the ambient pressure, it is referred to as underpressure / vacuum.

The measurement result can be output as a pressure change or as a leakage rate in various units.

The simple design, the high reliability, and the price/performance ratio make the pressure drop method one of the most frequently used measuring methods, especially for small volumes and/or larger leak rates.

Test medium:

Compressed air/vacuum, nitrogen, hydrogen, helium

Detectable leak rates:

Volume- and pressure-dependent > 1 cm3 / min

Method:

Test item is subjected to pressure/vacuum. The pressure change caused by leakage is measured and evaluated.

Advantages:

- Simple, quick and inexpensive method

- Manageable tools

- Few requirements for operating and maintenance personnel

- Automated test procedure in mostly 4 phases:

- Filling/evacuation

- Stabilise

- Measuring

- Venting/airing

- Worker independent assessment

Disadvantages:

- Usable pressure difference resolution depends on test pressure and volume, thus rarely applicable for leak rates < 1 cm³/min

- Thermal and elastic changes on the test specimen influence the measurement result