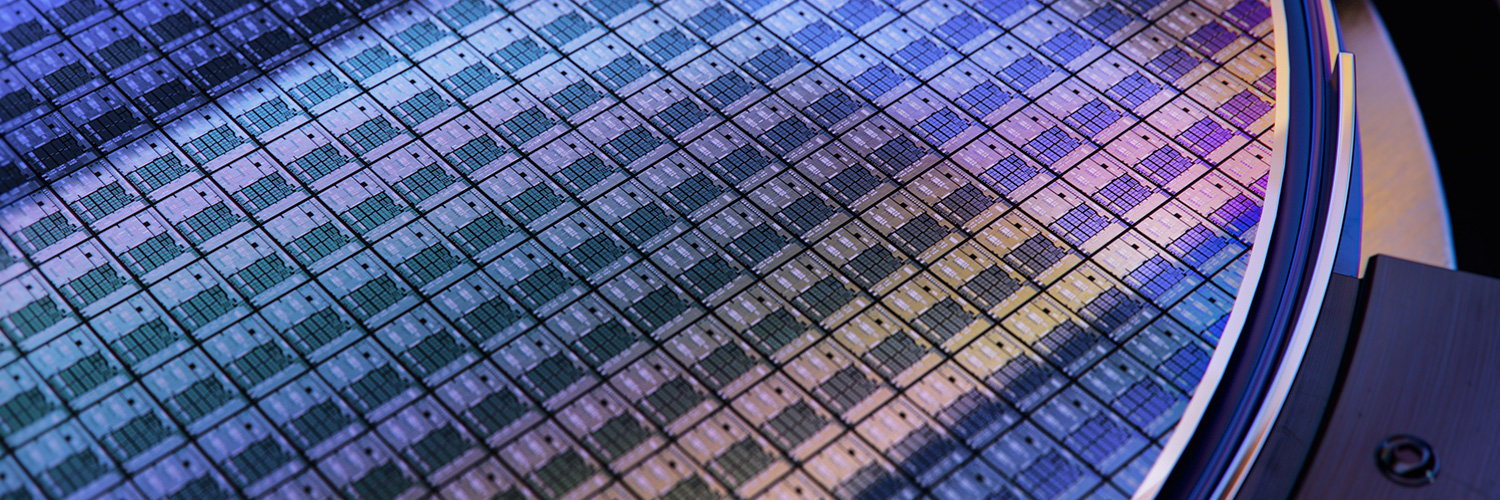

Leak testing for the semiconductor industry

The semiconductor industry is rapidly evolving, with a constant push for smaller, more powerful chips. Manufacturers of sub-assembly parts are under pressure to deliver, with no room for error or defect.

Parts and components such as stage and monitoring systems (EUV/DUV lithography, etc.), cooling systems, electrical components, seals and gaskets, optics and sensors, etc., all must be tested with the highest level of control and precision to ensuring quality in the manufacturing process. With such small, intricate processes, there is little to no margin for error.

Recognizing that the leak testing market was struggling to keep up with the sector's evolving needs, innomatec developed a solution that not only met but surpassed the stringent testing requirements this industry requires.Air leak testers designed to meet the stringent requirements of the semiconductor industry

Manufacturers of subcomponents for the semiconductor industry need high-precision leak test measurement and accuracy, the ability to monitor and record results to prove quality, and a copper-free design to avoid the corrosion risk that is much higher between the very small, micro connections of these types of machines.

innomatec designed the LTC-902 SI multi-channel leak tester model to meet these needs that were not being met by the market. This SI model delivers the same flexibility and elite precision as our standard LTC-902, but built with premium components for a fully copper/brass-free design.

In the semiconductor industry, where the smallest leaks could result in costly failures, innomatec’s LTC SI model delivers unparalleled accuracy, capable of detecting even the tiniest leaks. This model will ensure your sub-assembly parts meet the rigorous standards of the semiconductor industry while complying with stringent requirements.

LTC-902SI multi-channel leak tester

Copper-free design to mitigate risk of corrosion in micro connections

The LTC SI model has a special copper-free design to mitigate the increased risk of corrosion between the very small, micro connections of these types of machines. Without this copper-free air leak testing option, manufacturers’ only option is to test using tracer gas/helium leak testing methods, which is more complex and costly.

High-precision measurement and accuracy

The LTC SI model delivers the reliable pressure control and accuracy required by the semiconductor industry. innomatec’s LTC models are flexible and configurable, capable of performing various types of leak tests, including pressure change method, pressure differential method, pressure increase method, mass flow method, dosing (or “closed component”) method, and more.

Monitor and record leak test processes, integrate data into your system

innoRC is a unique software feature that allows remote control of innomatec's leak testing devices through a Windows application. innoRC allows manufacturers to monitor and record every moment of a leak test process and integrate data seamlessly from your LTC leak tester into your control systems using a DLL, offering the ability to analyze and prove the quality of your processes.

Leak testing applications in the semiconductor industry

innomatec’s leak testers offer the accuracy and reliability you need to meet the stringent requirements of the semiconductor industry. We have a variety of leak test models with the high performance and flexibility to test the many components and assemblies that need to be leak testing in the semiconductor industry, including:

Stage and Motion Control Systems

- Verify the integrity of the stage and motion control systems.

- Check for leaks or contamination that could affect precision and accuracy of processes, such as EUV/DUV lithography.

Cooling Systems

- Inspect the cooling circuits and connections for leaks.

- Confirm that the cooling systems are functioning optimally, as systems like those used for EUV/DUV lithography generate significant heat during operations.

Electrical Components

- Test for any leaks or contamination around sensitive electrical components and connections.

- Ensure that no moisture or other contaminants have infiltrated these areas, which can lead to electrical malfunctions.

Seals and Gaskets

- Inspect all seals and gaskets for any signs of wear or damage.

- Test for leaks at critical sealing points to prevent contamination.

Exposure Optics and Sensors

- Ensure that the exposure optics and sensors are free from any contamination or debris.

- Leak testing can help prevent any gases or particles from infiltrating these critical components.

Discover innomatec’s innovative solutions for this rapidly evolving industry

innomatec is at the forefront of this rapidly evolving industry. For over 40 years, innomatec has worked with the biggest manufactures in Europe and across the globe, helping them solve test problems on their manufacturing lines to ensure the highest product quality. We continue to innovate, using our decades of skill and expertise to design solutions that meet and exceed the needs our customers.

Need help with your semiconductor leak testing application?