Turnkey Helium Sniff Leak Detection System – MHLS 100

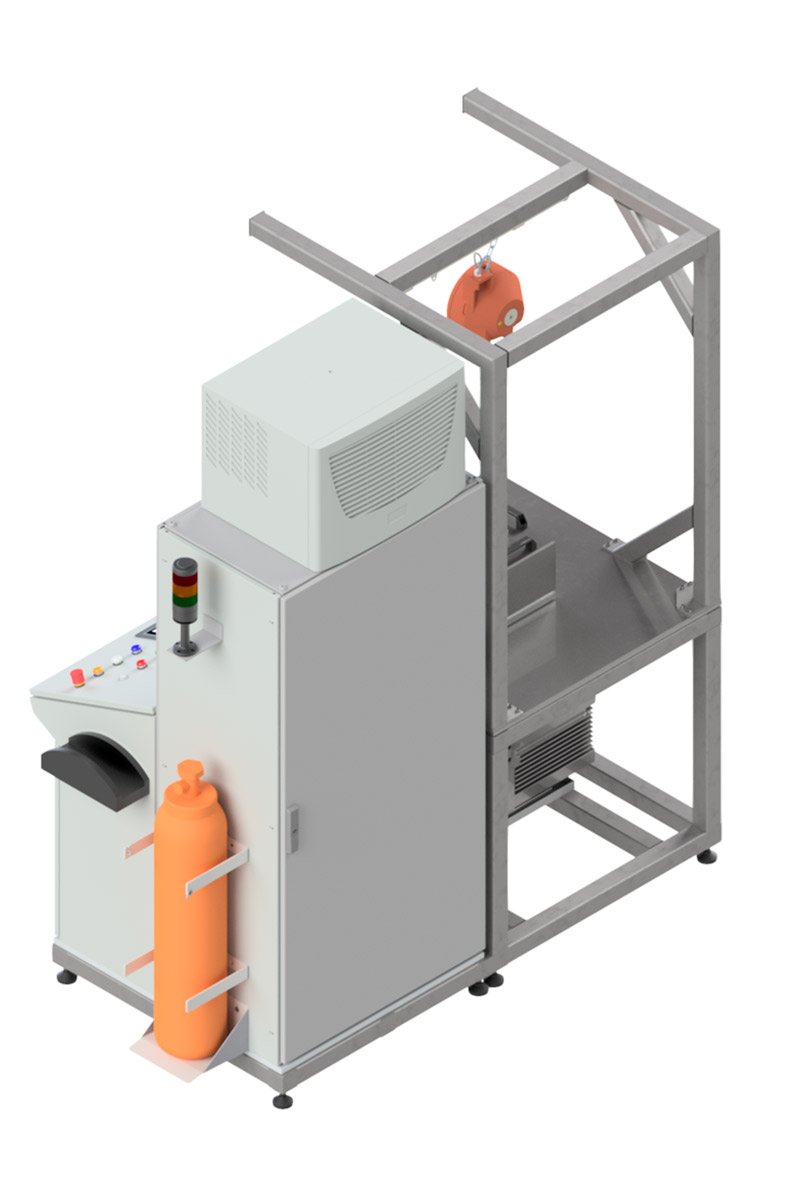

The MHLS 100 modular helium leak detection system is a turnkey station that makes it easier to add manual or automatic sniffer leak detection to your production line. Configure this fully engineered, standard system to meet your requirements and reduce the time and cost to implement trace gas leak testing.

Based on the hundreds of systems built by innomatec for helium or forming gas testing, you can be assured the MHLS 100 covers all the important factors and requirements to deliver accurate testing.

Everything you need for accurate trace gas sniffing in a standard platform – configured for your requirements.

MHLS 100 Trace Gas Leak Detection System Description

The MHLS 100 can provide either manual leak detection with a hand-held sniffer probe or an automatic sniffer test using a robot. You can opt to use helium or forming gas (5% hydrogen / 95% nitrogen). The system consists of a stable base plate, which is mounted on either machine feet or castors, 2 of which are swivel castors with parking brakes. All necessary connections as well as the test gas supply and disposal (exhaust systems) are easily accessible.

The MHLS uses a Siemens TIA Portal PLC control system, with all control and signaling devices mounted on the control panel. All system statuses, visualization of process sequences and error messages are displayed and manual/automatic operation is controlled via the 7” touch display. Indicator lights in the operator's field of vision provide good/bad indication.

The vacuum pump technology with all the necessary components, as well as the filling and evacuation technology, is housed in a separate cabinet at the rear. The Inficon LDS 3000 trace gas detector is equipped with an XL sniffer probe and can therefore be used for measurements in the high and low flow range. The holder for the sniffer probe and its hose (manual) or connection for the sniffer probe (automatic) are easily accessible.

Worker guidance

The MHLS 100 was developed to minimize the influence of the worker on the usually completely manual leak detection process. The MHLS software intercepts or controls measurement errors or inaccuracies due to non-compliance with important process steps.

This includes the following functions, some of which can be switched on and off:

- User administration with different authorization levels

- Up to 50 different test parameter sets

- Minimum filling time (safe filling of the test specimen)

- Minimum mixing time (safe uniform gas concentration in the entire component)

- Minimum sniffing time (no premature termination of the measurement process possible)

- Refill helium if leakage is very high

- Number of limit leakage rates exceeded

- Curve progression can be exported (for measurement tests and analyses)

- Manual mode

Technical specifications

- Test method: Helium/forming gas leak detection

- Test part connection: Single or multiple

- Test medium: Helium (4.6), air/helium mixture (90/10 %) / forming gas (%5 hydrogen / 95% nitrogen)

- Utilization: 3 shift

- Technical availability: 95 %

- Compressed air supply: min. 6 bar (for air quality, see General Conditions)

- Electricity supply: 400 V / 50 Hz (rated short-circuit current at the feed-in point ≤ 5kA)

- Surroundings:

Temperature 15 to 35° and max. 50 % humidity (no air conditioning)

Temperature > 35° C Air conditioning for switch cabinet and leak detector / vacuum pump (optional) - Exhaust air: according to later layout specification

- Test pressure range:

A: 5 - 200 mbar (rel.) automatically regulated

B: 0.2 - 5 bar (rel.) automatically regulated

C: 2 - 16 bar (rel.) automatically regulated

Standard is 1 test pressure range (A, B or C) - Optional: 2 test pressure ranges (any combination of A, B, C possible)

- MHLS has a test pressure output with two pressure ranges - Detectable leakage rate: 1 x 10-1 to 1 x 10-5 mbar*l/s (depending on gas concentration and test task)

- Test cycle: ≤ XX seconds / part (excl. part handling)

The test cycle time is calculated from the start triggering to the completion of leak detection (with a proportion of "gross leaks" and "solid leaks" < 1 %) - Review of the Measurement technology: Manual on optional test leak

- Test leak: optional

- Test pressure present query: optional

- Pressure increase: Optional as add-on unit

- Mixing station: Optional as add-on unit

- Mixing station: Optional as add-on unit

- Helium recovery device: Optional as add-on unit or standalone unit

Items with * are customer-selected features and options.

Options

innomatec also offers a range of useful options to further improve the utility of the system in your factory, such as:

- Handheld scanners

- Label printers

- He bottle test leaks

- 2nd test pressure range for test gas (two individual test pressure ranges)

Contact us to discuss your requirements and to learn how the MHLS 100 can meet your trace gas sniffing requirements.

Fully turnkey leak detection system, from start to finish

Our experts will help you determine the configuration of the MHLS 100 to work within your manufacturing process. From consultation to commissioning at our factor to complete and detailed system documentation, we provide a total solution for your trace gas leak test.

We are also happy to advise you

by telephone at +49 (0) 6126/95 98 66 800.