Leak testing for electric vehicle manufacturing

The electric vehicle industry is in a period of rapid growth. New products, government regulations and manufacturing standards are constantly evolving. Maintaining the quality of these components and assemblies is of utmost importance - and depends on accurate, reliable testing methods for manufacturing.

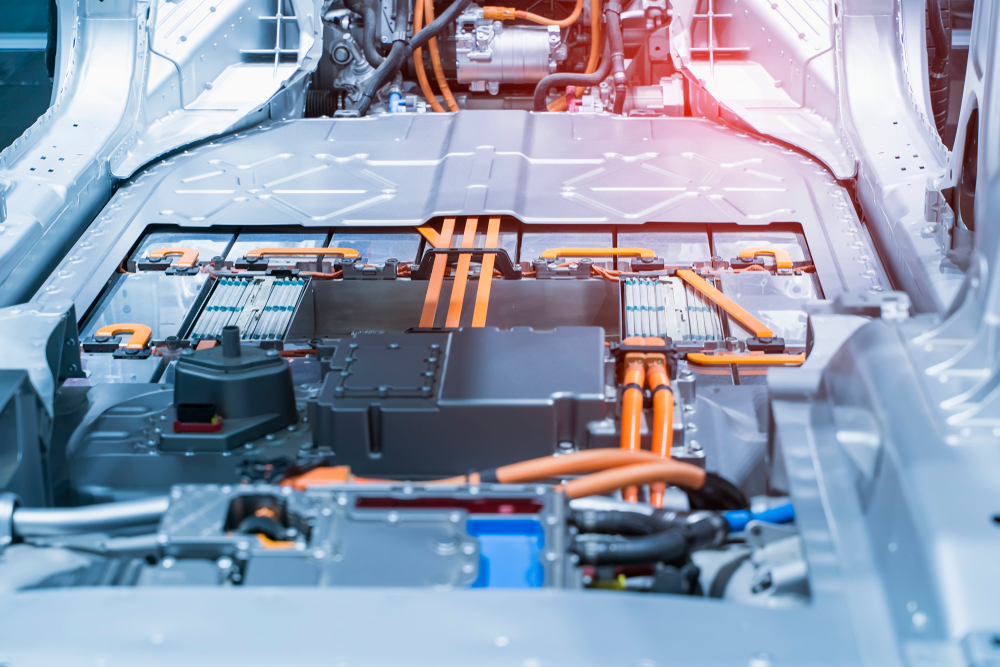

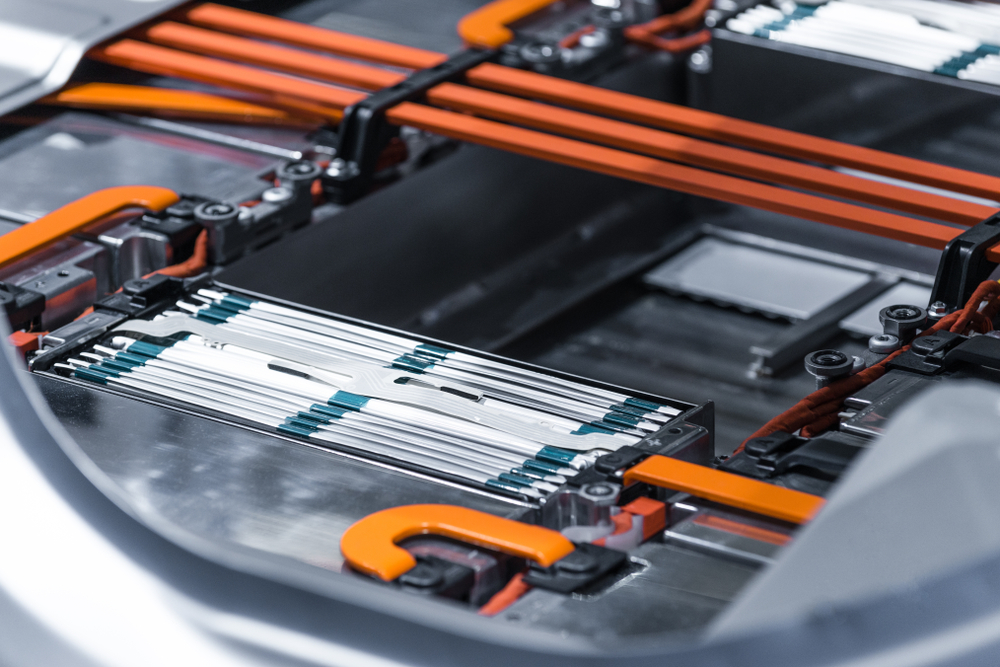

When it comes to leak testing, the electric vehicle battery and its components are important elements to test. Once a battery case and/or component is produced, there are many important quality checks that must be performed, including visual weld inspection, assembly checks, dimensional checks, temperature checks and cleanliness checks, but none is perhaps as important as leak testing. The leak test provides the best indication of whether your battery is functioning correctly in the field.

innomatec has decades of experience working with the world's largest automotive manufacturers and continues to provide the most efficient and cost-effective solutions for our customers who focus their attention on developing and continuously improving their electric vehicle battery systems and components.

We can help you overcome the challenges of leak testing electric vehicle batteries and find which leak testing method is best for your application.

We offer a wide range of solutions for leak testing ofcablesInvertersConnectorsControl UnitsBattery Housingand much more.

Proven leak testing of electric vehicle batteries and components

Leak testing of electric vehicle batteries and components can be particularly difficult due to the nature of the parts being tested. The environmental conditions, the size of the parts and components, the varying stability of the parts and the sample temperature all present challenges in achieving the required measurement accuracy and repeatability. The most important question when choosing the best leak test method is whether to use air or helium. The goal is to achieve high-quality results - and innomatec helps you achieve this.

The most important question when choosing the best leak test method is whether you want to use air or helium.

Air methods include:

Helium methods include:

Which method is most suitable depends upon your specific application, the part to be tested, the test environment, etc.

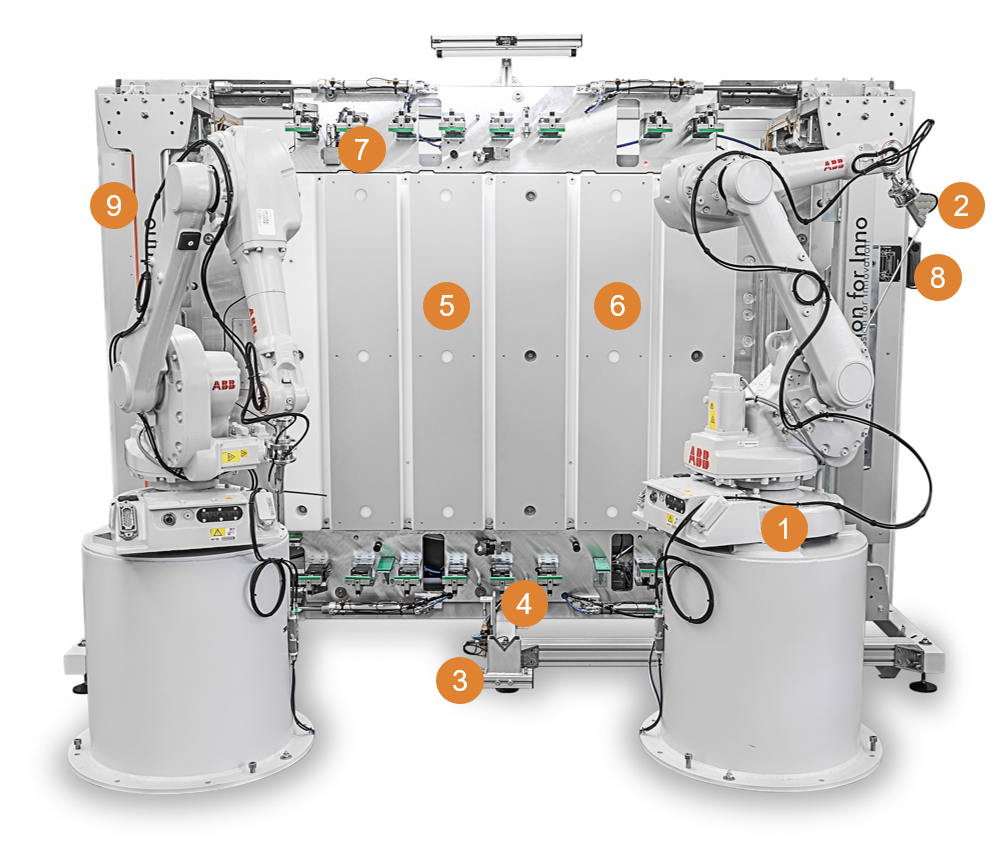

Below you can see an example of a system that is used for EV components designed to meet the customer's requirements for leak testing and automation.

- Robot-guided leak detection

- Sniffer tip with collision protection

- TCP correction

- Automatic test leak measurement

- Packing for volume reduction

- Leak test by leak test computer LTC 902-M with mass flow method

- Temperature measurement

- Mobile operating panel

- Functional sealing system

- Battery cover

- Battery housing

- Battery modules

- Bursting diaphragms

- Busbars

- Cable harnesses

- Cast iron housing

- Cells

- Connectors

- Control modules

- Converter

- Cooling cables

- Cooling plates

- Diaphragms

- Equalisation tank

- High-voltage connectors

- Inverter

- Low-voltage connectors

- Motors

- Prismatic cells

- Radar sensors

- Rotors

- Stator housing

Achieve the best results for your electric vehicles with solutions from innomatec

The electric vehicle market is constantly changing, and our engineers are always up-to-date with the latest industry requirements and have the tools and knowledge to test your parts and ensure the quality and safety of the parts you produce. Our team loves a challenge and will work with you to ensure you produce the best possible parts and assemblies.

Contact us to learn more about our electric vehicle battery leak testing solutions and discuss your application.