Leakage and functional testing for valves and fittings

Leak detection procedures must be performed to maintain the integrity and effectiveness of valves, fittings, and faucets. Leaks can negatively impact efficiency, drive up energy costs and, in the case of hazardous materials, create unsanitary and potentially dangerous circumstances.

When leak testing fittings and valves, manufacturers face several challenges, including testing many part variations, which can each require the combination of multiple leak test procedures, and often functional test procedures. innomatec designs turnkey test benches and machines to ensure the most accurate and efficient testing of valves and fittings.

Eliminating leak defects in faucets, fittings, and valves

Many tests must be performing on valves and fittings to ensure they meet product quality requirements. These tests include potentially various types of leak tests, as well as a wide variety of functional testing. It is not uncommon for leak testing to combine several measurement methods, for example the helium vacuum integral method for external leakage, coupled with flow or volume measurement, or other special methods for functional and assembly verification. Depending on throughput goals, the number of different product types being tested on one machine, etc., machines can be designed to accommodate several measurement methods and functional tests, with manual and/or automated features such as robotic handling with changing grippers, a light table with camera positioning, and more, to meet a manufacturers’ needs.

Methods and technologies used for valve leak testing

There are many different valve and fitting testing applications across many industries, including, plumbing (faucets, mixer valves, etc.), refrigerants, HVAC (heating systems), automotive (fueling systems, etc.), food processing, flow cells, and more. Depending on the different materials, designs, and requirements of these specific parts and applications, a variety of different leak test methods can be used. The majority of cases will use either helium or air leak test methods—both well-served using the power and flexibility of the LTC-802 or LTC-902, depending on your needs.

For part designs and applications that require testing to very low, strict leak rates, like valves used in the food processing industry, gas / refrigerant applications, helium is often used to ensure the most accurate leak detection of even the smallest leaks. However, for general plumbing applications, including faucets and water taps for a residential home, the leak rates are higher, so air can often be used to sufficiently detect leaks.

Reliable Sealing Solutions for Valves and Fittings

A crucial component of an accurate, reliable leak test for valves and fittings is having strong seals and connections. Due to the complex and varying nature of valve and fitting designs, special attention must be made to ensure an adequate seal. Factors such as the diameter, type of sealing head, test pressure, sealing angle, and more must be considered in a test design. innomatecs connec® quick connection systems are designed with these factors in mind, offering clever solutions to deliver the most efficient fixture and sealing systems possible.

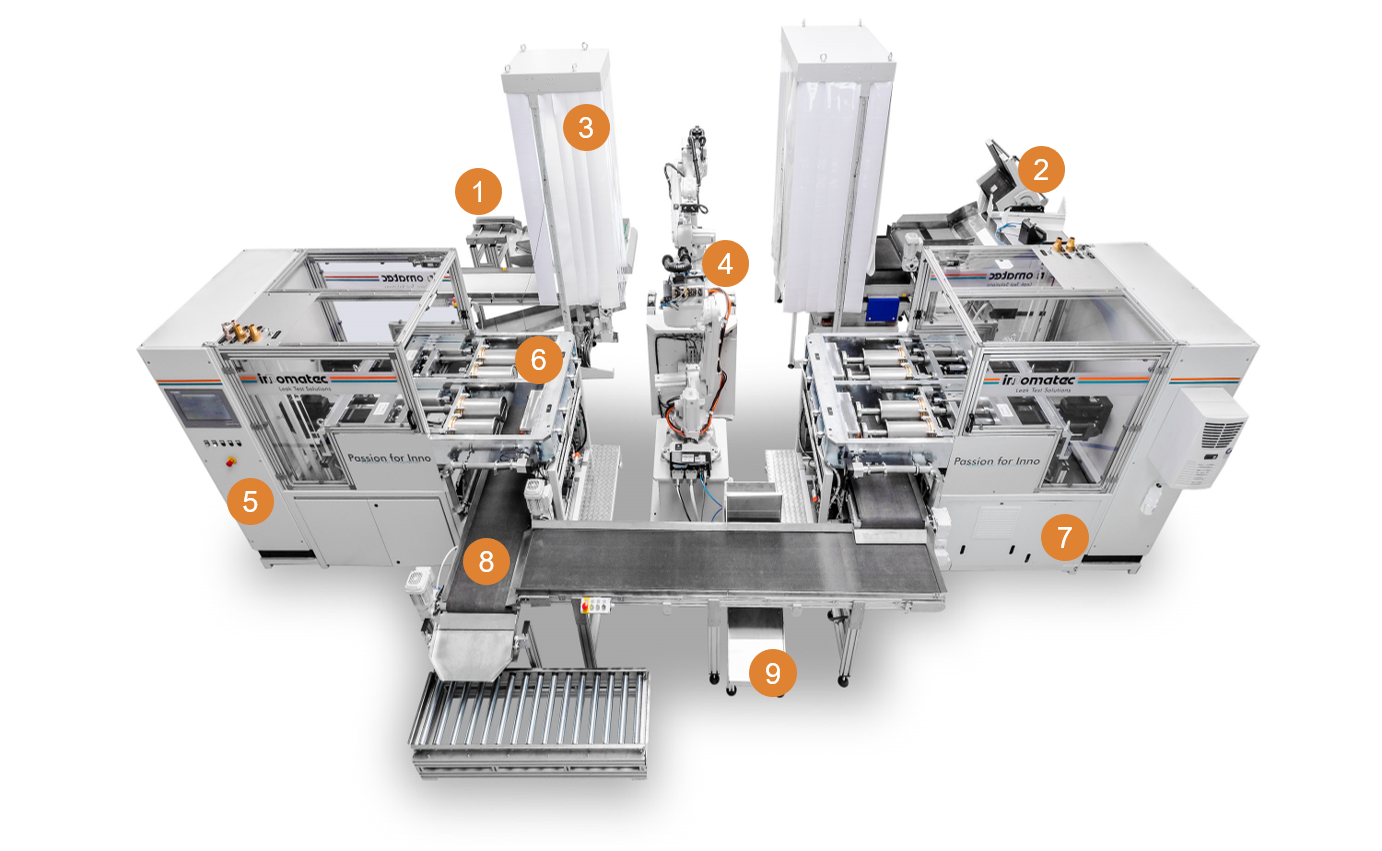

Below you can see an example system that is used for fittings and valves and meets all customer requirements for leak testing and automation:

- Feeding shaft parts

- Feeding of bulk material

- Light table with camera positioning

- Robot handling with interchangeable gripper

- 4-fold helium testing system

- Servo-driven universal sealing system

- Maintenance-friendly pumping station

- Good part ejection

- Reject sorting

- Aluminium housing

- Automotive valves

- Ball valves

- Closure caps

- Concealed fittings

- Filling valves

- Food valves

- Gas fittings

- Gas pressure regulator

- HVAC valves

- Pipes

- Plug-in/solder connectors

- Press-Fittings

- Sanitary fittings

- Screw fittings

- Screw fittings

- Thermostats

- Thread adapters

Consult the leak test experts—a team you can trust!

innomatec has over 40 years’ experience in the field of leak detection for valves and fittings. We know that even small leaks can lead to costly downtime, plant damage, and safety risks. That's why we offer comprehensive leak testing services to accurately detect, investigate, and diagnose any potential problems.

Don't let leaks compromise the efficiency, safety, and reputation of your operation. Contact us today to make an appointment to discuss your leak test! Our leak test experts will take the time to meet with you, learn about your application, and answer any questions you may have to ensure your team gets the best test solutions for your needs.