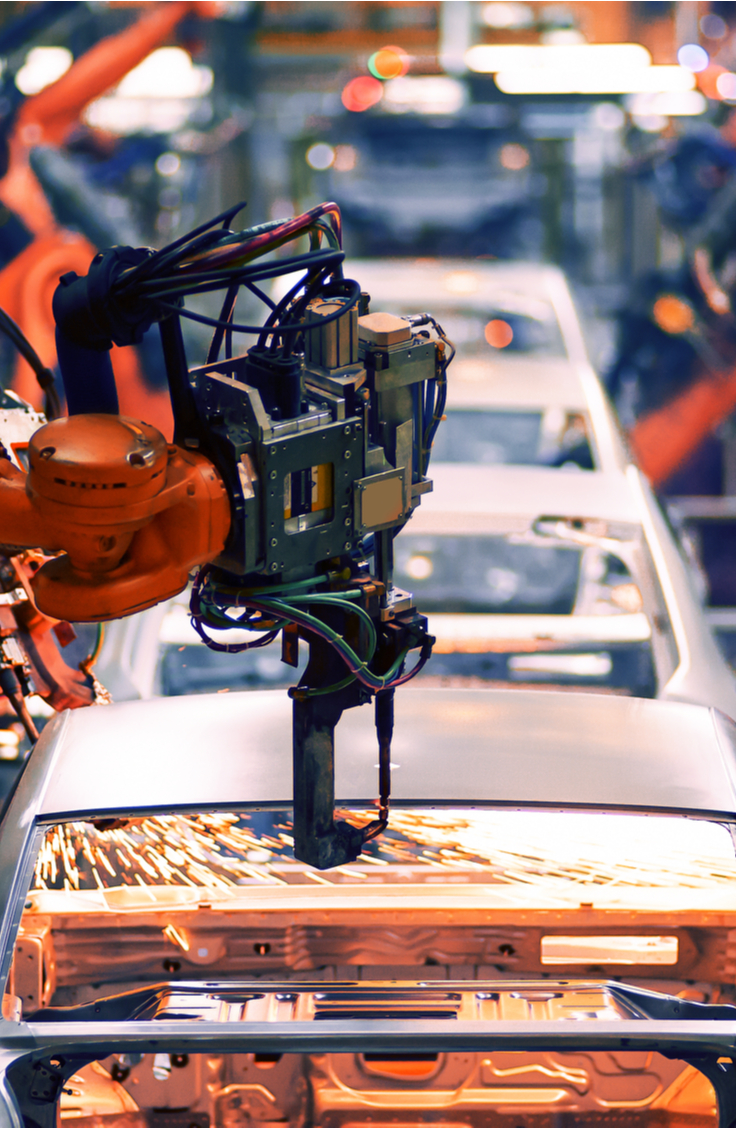

Leak and function testing for the automotive industry

Leak testing is an essential part of the automotive manufacturing process to ensure vehicle safety and reliability. A leak can occur in various systems of a vehicle, e.g., the fuel system, exhaust system, cooling system and brake system. Leaks can lead to problems: loss of power, lower fuel efficiency and even fires. These faulty, leaking components result in recalls, rework, etc., and thus not only cause financial damage to your company but, in the worst case, can pose a health and safety risk to everyone.

As specialists in leak testing for automotive manufacturing who know the specific requirements of the industry, we can help you avoid these risks. In-depth specifications or requirement specifications, which place high demands on the documentation and design of the systems require reliable and suitable solutions for leak testing.

With modular interchangeable tool systems, for example, flexible production is possible without any problems, so that call-off numbers can be accommodated. To meet the demands of the industry, our software provides one hundred percent traceability and high system availability with low maintenance requirements.

Find out more about our leak test expertise in the automotive industry below or contact us to discuss your upcoming project.

Leak testing of automotive components for maximum safety

By carrying out regular leak tests, car manufacturers can detect and correct any problems before they become serious. A leak can occur in different systems of a vehicle, e.g. the fuel system, exhaust system, cooling system and brake system.

There are different methods for leak testing components used in vehicles. One common type of leak test is pressure change measurement , which involves pressurizing a system and measuring the rate of pressure drop. This makes it easy to detect leaks in large-volume parts such as engines, coolant tanks and other components.

Another solution is leak testing with helium/tracer gas. Here, the test gas is introduced into a component, and leaks are detected with the help of specially-made test equipment. This method has the advantage that smaller leak rates can also be reliably detected in larger components, including batteries, airbags or fuel filters.

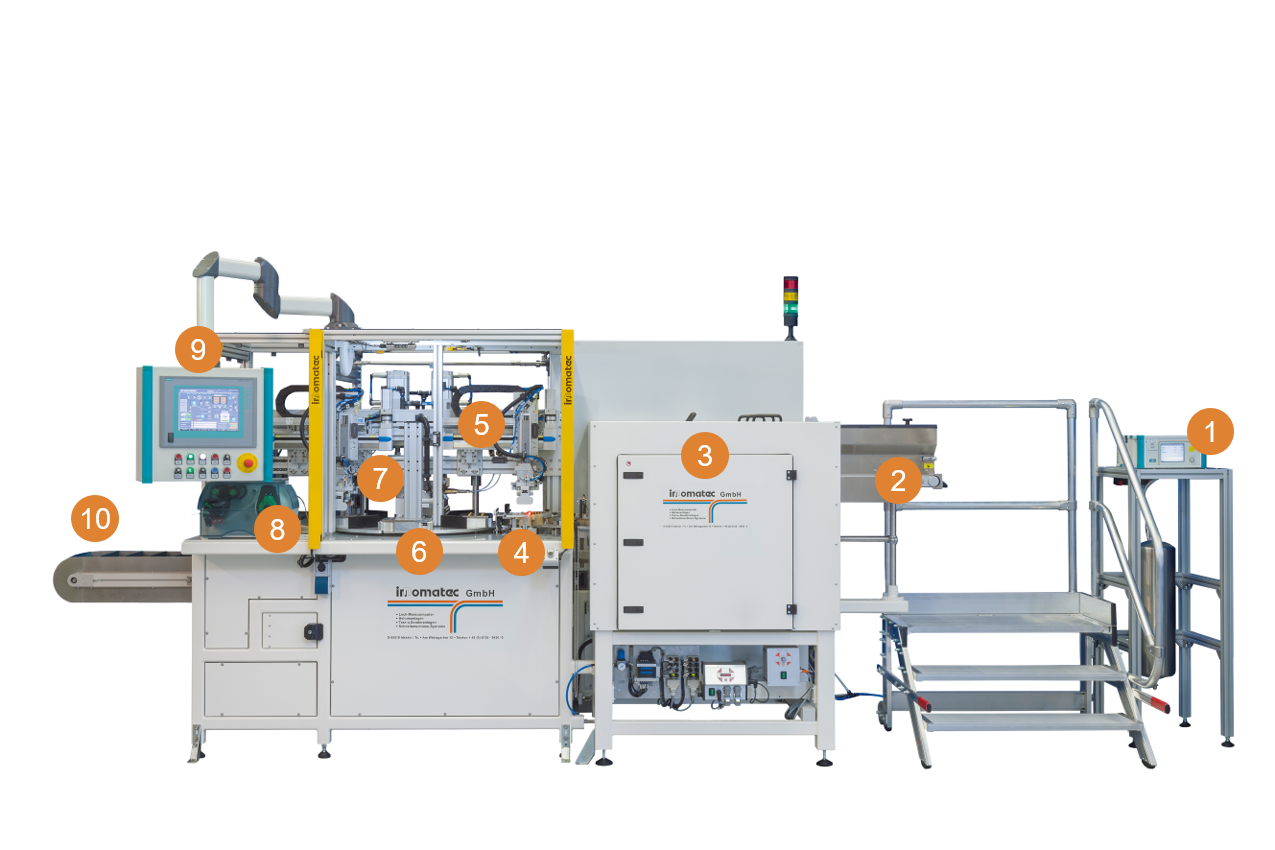

Below you can see an example of a system used for automotive components that met all customer requirements for leak testing and automation:

- Helium mixer (10-50% He/N2)

- Bunker

- Vibratory bowl feeder

- Automatic separation

- Pick & place system

- 4-fold rotary indexing table

- 1x10-6 mbar*l/s helium leakage test

- Label printer

- Swivelling HMI

- Clocked belt for IO components

- ABS modulator

- ABS sensors

- ABS valves

- Activated carbon tank

- Air filter box

- Air flow meter

- Air suspension struts

- Airbag igniter

- Aluminium housing

- Antenna motor

- ASR valves (anti-slip)

- Batteries

- Belt tensioners

- Brake cylinders

- Brake lines

- Carburettor

- Castings

- Catalytic converters

- Central locking systems

- Clutch master

- Compensators

- Condensers

- Control modules

- Crankcase ventilation

- Cylinder head covers

- Cylinder heads

- Diesel injection

- Door closing delays

- Drives

- Dryers

- EGR cooler

- EGR valve

- Engine block

- Evaporator

- Exhaust manifold

- Exhaust manifolds

- Exhaust systems

- Expansion tank

- Expansion valve

- Feed pumps

- Filters

- Fuel distribution manifolds (rail)

- Fuel lines

- Gas struts

- Gearbox

- Gearbox switch

- Headlights

- Heat exchanger

- Hydraulic valves

- Indicators

- Injection nozzles

- Injection ramps

- Injection valves

- Injectors

- Intercooler

- Mass air flow sensor

- Microswitch

- Nozzles

- Oil separator

- Oil sump

- Pistons

- Pneum. Seat controls

- Pneumatic valves

- Power steering systems

- Pressure sensors

- Pressure switch

- Pumps

- Radiator

- Radiator caps

- Radiator hoses

- Relays

- Sealing rings

- Sensors

- Silencers

- Solenoid valves

- Suction jet pumps

- Tanks

- Thermostats

- Tubes

- Tyre valves

- Valve seats

- Window regulator

- Windscreen wiper motors

Reliable leak testing solutions for the automotive industry based on 40 years of experience

innomatec has over 40 years of experience in leak testing for the automotive industry. We have worked with renowned manufacturers both locally and worldwide and offer reliable and accurate leak testing tailored to your planned production periods and call-off quantities.

Our staff has extensive knowledge and experience in all relevant testing procedures. We use state-of-the-art equipment and follow strict quality control measures to ensure our services meet the highest industry standards and specific OEM requirements and standards.

Contact us to discuss your testing needs. We will create a customized solution for you.