Burst Pressure Test with Air

The bursting pressure test method with air is particularly suitable for test items that must not be burst by means of a liquid.

Burst testing with air is the most effective method for testing items that are usually very small, but also for parts containing highly sensitive components that are to be monitored until the point of failure.

An example is a safety valve, especially for gases. Switching point monitoring by gas. If this fails, there is the possibility of bursting.

The pressure increase can be abrupt, pulsating or uniform over a ramp. Depending on the desired sampling rate and accuracy, this can be displayed as a pressure value over time in a graph.

The burst test systems must be designed and constructed in accordance with the applicable safety guidelines to endanger the operator and the production environment.

Test medium:

Air / Nitrogen

Burst pressures:

Stepless from 0.01 - 50 bar (maximum test pressure depending on component volume)

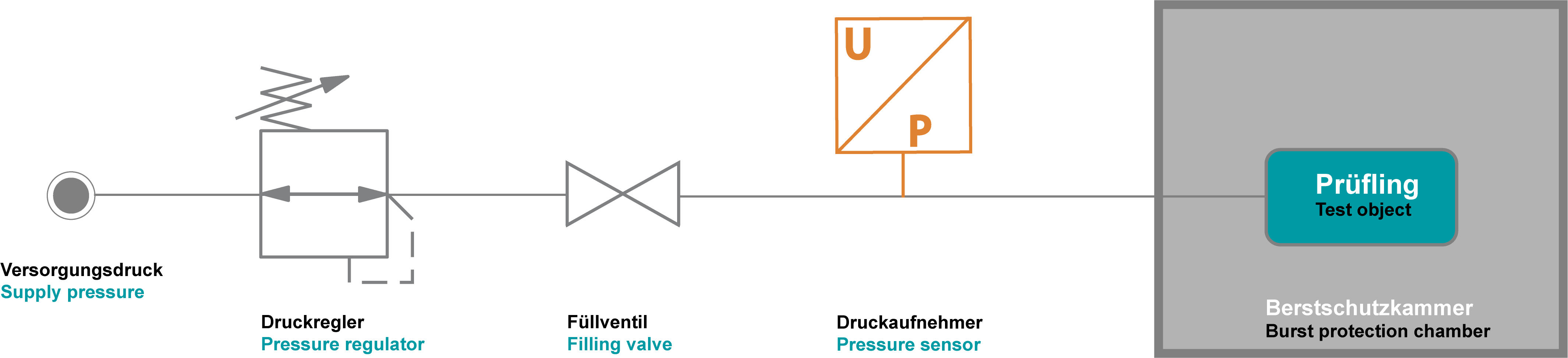

Method:

The test specimen is filled with the test medium and caused to burst. The bursting point or the pressure curve are recorded by the system.

Advantages:

- Very inexpensive and accurate measuring method

- Testing of moisture-sensitive components, which must remain dry during measurement

- No handling of liquids, such as oils or water

Disadvantages:

- High demands on machine safety because of compressible medium (high stored energy)

- In case of bursting, the compressed gas quantity is released abruptly, resulting in a loud bang

- Danger from possible flying parts