Underwater Visual Inspection

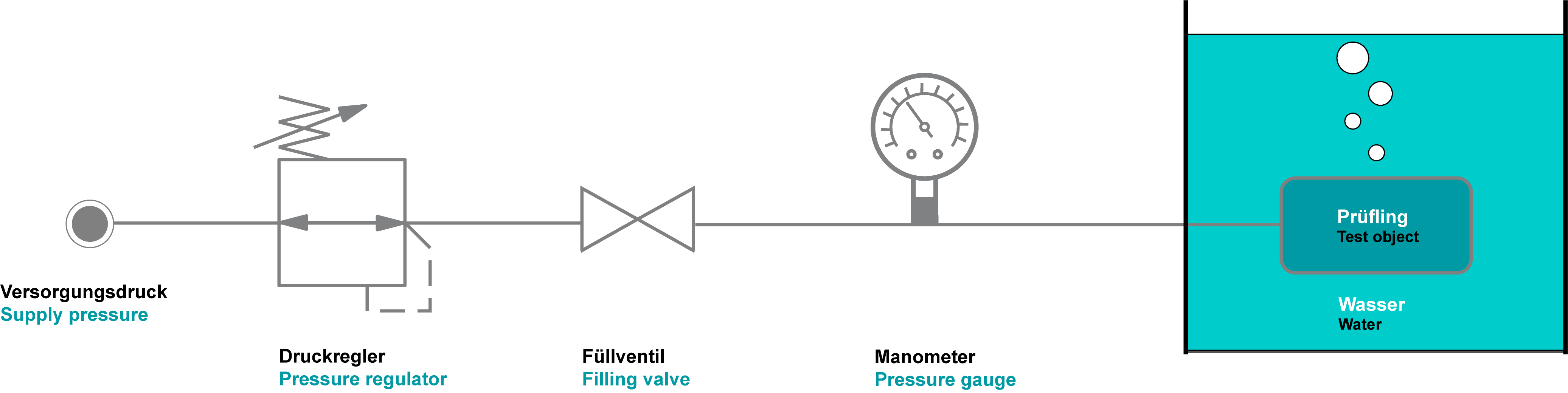

The underwater visual inspection is the most basic leak test method and combines the actual leak test with leak detection.

A gas-filled test item is pressed under water or partially wetted with water and then visually inspected by an operator.

The independence of environmental conditions such as temperature, draughts, vibrations, etc. makes it possible to detect very small leaks under prolonged observation. In some cases, smaller than with pressure change methods. Even temperature-treated, unstable and very large components can be tested for leaks under water, sometimes at very high test pressures.

For some special applications, underwater visual inspection is still the most efficient leak testing solution.

If the leak position is important and the leak rate is modest, then the underwater visual inspection can be a suitable measuring system.

Test medium:

Air / nitrogen

Test pressures:

Stepless from 0.01 - 1,000 bar

Detectable leak rates:

Depending on volume and component < 1 x 10-4 mbar*l/sec (1 bubble with 1mm diameter per 35 sec).

Method:

The test specimen is filled with test gas and immersed in a water bath. The air escaping through a leak forms air bubbles which then rise and can be detected by the operating personnel.

Advantages:

- Very cheap and accurate measurement method

- Very exact detection of the leak position

- Not dependent on all environmental conditions (temperature, draught, sunlight, etc.)

- Not dependent on the stability of the test object (small volume changes, vibrations, etc.)

Disadvantages:

- Components become wet on the outside

- Handling of test water required

- Operator-dependent evaluation