LTC-503 is high-performance entry-level leak testing made easy

The first in our new generation of leak test systems, the new LTC-503 is an entry-level leak tester like you’ve never seen before. Engineered innovation delivers high-performance measurement in a durable, robust design and its all-new interface simplifies your leak testing. The feature-rich LTC-503 is built on over 40 years of leak testing expertise and is suitable for a broad range of standard applications.

ACCURATE & RELIABLE

Can detect very fine leaks, down to 0.1 Pa

EASY TO USE, NEW UX!

Simple operation and intuitive control with a new user interface

CHOOSE FROM 5 LEAK TEST METHODS!

Unique to the LTC-503, get more choice in a starter leak tester (see below)

EASY TO INTEGRATE

Set up is simple so you can start testing quickly

ADVANCED TESTING FEATURES

BUILT TO PERFORM

From extreme long-life valves to high accuracy sensors, LTC-503 has many performance and reliability updates

MANY OPTIONS

From connectivity to languages,

review all specifications >

ECONOMICAL

Request an offer for a quote on this cost-effective option!

FAST DELIVERY

Worldwide delivery in no time!

Choose from 5 different leak test methods

One of the many benefits of the LTC-503 is its impressive flexibility as an entry-level leak tester. It is uniquely capable of operating one of 5 different leak test methods.

The Pressure Change Method (A) with absolute/relative pressure sensors is one of the simplest and most reliable methods for leak testing. The test object is subjected to overpressure or vacuum, and the pressure change over time is recorded.

PRESSURE CHANGE TEST TYPES

- Pressure/Vacuum Decay - Leak Standard

- Pressure/Vacuum Decay - ΔP

- Pressure/Vacuum Decay - ΔP/ΔT

- Blockage Detection

- Membrane Test

- Hold pressure

- Stagnation pressure

Review the LTC-503 datasheet for detailed specifications.

The dosing method (D), also known as the “closed component” method, is used for completely closed components such as watches, cell phones or control units. The test specimen is placed in a measuring chamber (bell jar) and sealed. This chamber is pressurized via an evacuated or filled pre-volume. A leak in the test specimen changes the pressure ratio, which is detected by a pressure transducer (DA) or pressure difference sensor (DR).

DOSING METHOD TEST TYPES

- Pressure/Vacuum Decay - Leak Standard

- Pressure/Vacuum Decay - ΔP

- Pressure/Vacuum Decay - ΔP/ΔT

- Blockage Detection

- Dosing method (D)

- Membrane Test

- Hold pressure

- Stagnation pressure

- Automatic volume determination (C) option

Review the LTC-503 datasheet for detailed specifications.

As an alternative to the dosing method, the volume determination (C) is used to determine the volume of the test specimen. It offers the same pros and cons as the closed component approach.

A known pre-volume is filled or evacuated with a known test pressure and then expanded in the test specimen. The volume of the test specimen is determined with the resulting pressure.

The principle of volume determination can also be integrated into other measurement methods.

The Pressure Differential Method (R) with reference volume is the most common method for leak testing. A reference volume – either a small internal volume or an external volume such as a master test specimen - is pressurized together with the test specimen. After the stabilization time, the pressure change between the two volumes is measured using a highly sensitive pressure difference sensor.

PRESSURE DIFFERENTIAL TEST TYPES

- Pressure/Vacuum Decay - Leak Standard

- Pressure/Vacuum Decay - ΔP

- Pressure/Vacuum Decay - ΔP/ΔT

- Blockage Detection

- Membrane Test

- Hold pressure

- Stagnation pressure

Review theLTC-503 datasheet for detailed specifications.

The dosing method (D), also known as the “closed component” method, is used for completely closed components such as watches, cell phones or control units. The test specimen is placed in a measuring chamber (bell jar) and sealed. This chamber is pressurized via an evacuated or filled pre-volume. A leak in the test specimen changes the pressure ratio, which is detected by a pressure transducer (DA) or pressure difference sensor (DR).

DOSING METHOD TEST TYPES

- Pressure/Vacuum Decay - Leak Standard

- Pressure/Vacuum Decay - ΔP

- Pressure/Vacuum Decay - ΔP/ΔT

- Blockage Detection

- Dosing method (D)

- Membrane Test

- Hold pressure

- Stagnation pressure

- Automatic volume determination (C) option

Review the LTC-503 datasheet for detailed specifications.

Technical Specifications

Explore the technical specifications of the LTC-503, designed to deliver superior performance and reliability for all your leak testing requirements:

Housing (WxHxD)

340x190x300mm

Weight

8,5 kg

Display

5" 800x480 Multi-Touch Display

Electricity supply

24VDC

Test medium

Air / Non-aggressive gases

Operating humidity

Up to 90% (non-condensing)

Air quality

ISO 8573-1:2010 (2:2:2)

Compressed air or nitrogen only

Digital I/O

8 inputs and 8 outputs each, 24 V–1 A max.

Expandable to up to 24 inputs and outputs each

Start / Stop / Results / BCD

Options

The LTC-503 offers a range of customizable options to enhance your leak testing experience, providing flexibility and precision for various testing needs:- Test leaks

- Test status indicator light for improved visibility

- Vacuum generator for enhanced leak testing performance

- Test distribution system for multi-piece testing

- External ventilation for particle-laden test environments

- External marker for clear identification of test results

- Well-tested standard solutions supported by innomatec

Connections / Communications

The LTC-503 easily integrates with the manufacturing line, with a wide variety of connectivity and communicating options, as follows:

- Digital I/O for remote control

- Profinet, Modbus RTU/TCP, Ethernet/IP and TCP Socket for industrial integration

- MQTT, ActiveMQ, FTP and SAMBA for advanced connectivity

- OpcUA for seamless communication with modern control systems

- ElasticSearch integration for robust data handling and storage

- Export formats: CSV, Excel, JSON, XML via USB, FTP or SAMBA

Contact innomatec with any questions about connectivity requirements.

An ideal leak tester for machine builders: Balance cost & flexible performance

The LTC-503 is a cost-effective, entry-level leak tester, with all the functionalities your customers require—and more!

- Reduce engineering time:

Fast delivery times and a simple integration process; enable fast test setup, commissioning and run-off - Meet most common leak test needs:

Choose from 5 different leak test methods - Ensure customer satisfaction:

Deliver exceptional measurement quality, unparalleled capability and precise accuracy—AND a new and improved UX your customers will appreciate

The LTC-503 delivers unmatched value—economical without compromising on performance

The LTC-503 provides unmatched value for an entry-level leak tester. The LTC-503 offers a unique combination of new functionality and features that do not exist in other entry-level leak testers on the market. See how the LTC-503 over-delivers:

Better leak testing performance

- Shorter test cycles

- Better leak testing performance (speed + repeatability)

- Higher sensor range (DP sensor range to 300mbar)

New, intuitive UX and operation

- On-device display for quick access

- Simple, intuitive navigation, built from a smartphone UI concept

- Convenient organization of programs

- Easy to operate, minimizing training requirements

Simple integration & modularity

- 24 VDC Power supply

- Built-in PLC communication

- Modular design; adaptable for various applications

- Easy to scale

- System distribution

Connectivity & remote capabilities

- All common plant floor interfaces and protocols

- Remote Service & Support: Troubleshooting and updates from a distance

- Update Over-the-Air (OTA): Seamless software enhancements without manual intervention

- Remote Connection for Sales & Service: Easier customer support and monitoring

Durability & low cost of operation

- Strong industrial-standard hardware, built for reliability and long-term use

- Exceptional durability (16 million valve cycles), backed by an extended warranty (optional)

- 10x less energy consumption

- 10x service interval

New, advanced test features

- Venting options: Internally or externally

- Prefill phase: Fill parts quickly, lower cycle time

- Filling ramp: Slowly increase pressure for sensitive test parts

- Conditional batch test: User-defined batch testing options

- Membrane test: Ability to detect the presence of a membrane

- RAM air test: Special test methods

- Blockage detection: Ability to test for and detect blockages within a part

Experience the LTC-503’s new and improved UI/UX

What’s new:

- Smartphone-like UI and control

- Test parameter overview

- Screenshot feature

- Visualized test execution views

- Test curve graphics

- Enhanced test program management tools (history, copy, export)

- And more!

What this means for manufacturers:

- Less training

- Less pressure on operators

- Less time to configure tests

- Less time to detect quality issues

- Less time to optimize tests

- Less time to document results

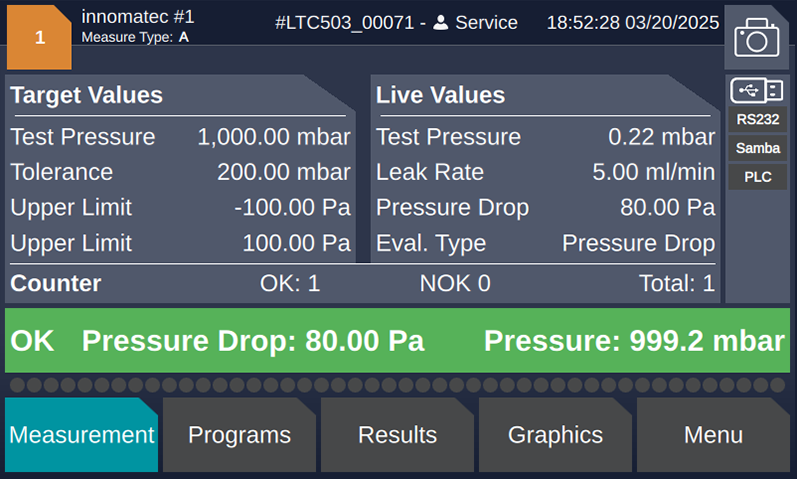

Measuring mask

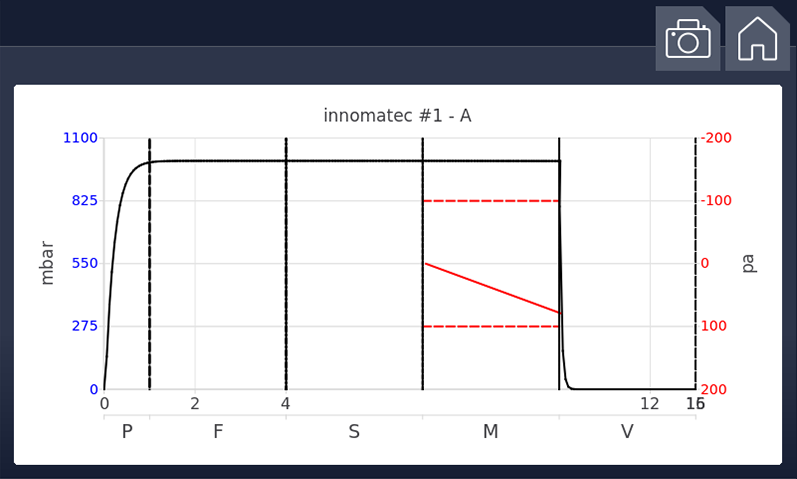

Graphic

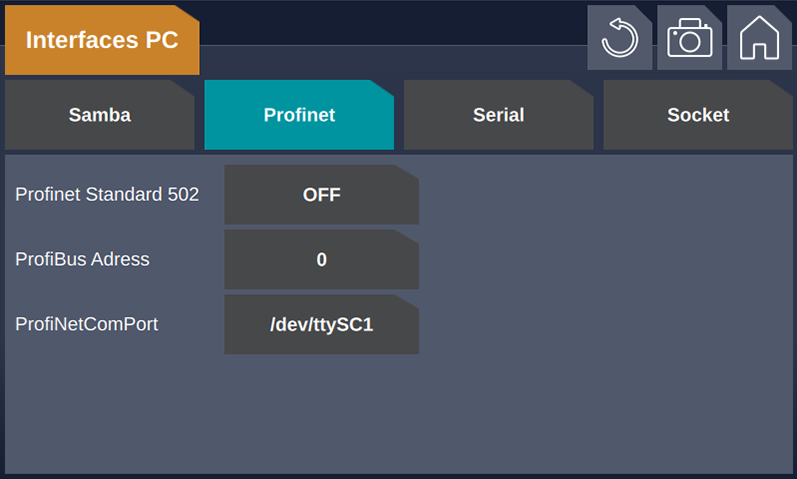

Interfaces

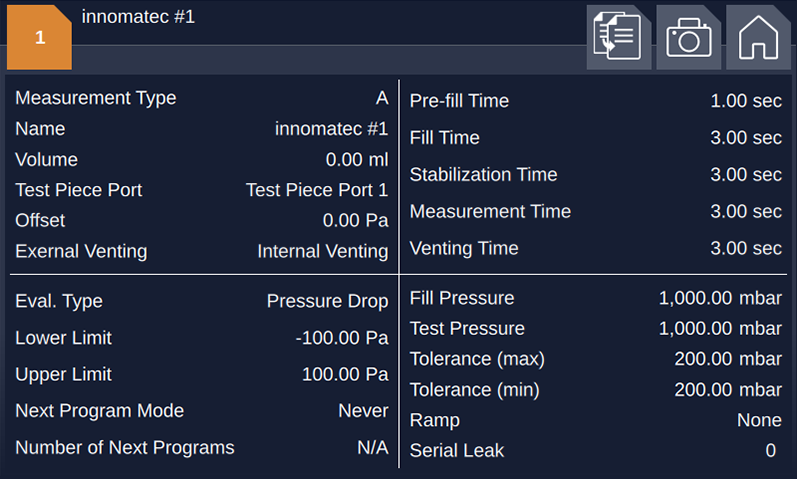

Parameter entry menu

The choice is simple: The LTC-503 makes leak testing EASY!

The LTC-503 is durable, flexible and offers the best leak testing performance from a standard, entry-level leak tester. Not only does it provide unmatched value, but it’s designed with manufacturers and operators in mind, to make leak testing AS EASY AS POSSIBLE.

- Easy intuitive UI

- Easy on your budget

- Easy to ensure the most accurate leak test results

- Easy to operate

- Easy to configure

- Easy to collect data in many formats

- Easy to scale or distribute

- Easy to get your solution with standard accessories

- Easy to stay safe and secure

- Easy to integrate on any machine and/or IT system

- Easy to get support from qualified leak test experts